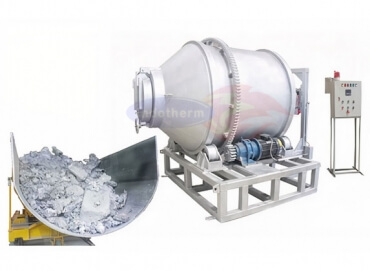

Twin Chamber Aluminium Melting Dry Hearth Furnace

Leading Exporter of Twin Chamber Aluminium Melting Dry Hearth Furnace in Delhi

Indotherm Equipment Corporation has specialized in manufacturing and exporting a wide range of Twin Chamber Aluminium Melting Dry Hearth Furnace in Delhi. Our dedicated efforts to customer satisfaction have gained us recognition among the top-tier manufacturers of Twin Chamber Aluminium Melting Dry Hearth Furnace suppliers in Delhi. Our products are highly advanced and manufactured as per the industry quality standards to meet international standards.

Our heavy-duty equipment is not only manufactured under strict supervision, but also gets tested under extreme quality conditions, so, our customers will get the finished products that are free from any flaw. We make sure that the products we, being one of the Twin Chamber Aluminium Melting Dry Hearth Furnace Exporter in Delhi, offer not only stand on the quality parameters but also beat the performance of its any other alternative if out in the market.

Top Quality Twin Chamber Aluminium Melting Dry Hearth Furnace Manufacturer, Exporter in Delhi

Our policy is to satisfy the demand of our clients, and we dedicatedly work on it. If you are interested in any of our products, so, feel free to tell us your requirements. As one of the most popular Twin Chamber Aluminium Melting Dry Hearth Furnace Manufacturer in Delhi, we are always ready to deliver your order at your place within a fixed time period. What are you waiting for? Give us a call or enquire us to get in touch.